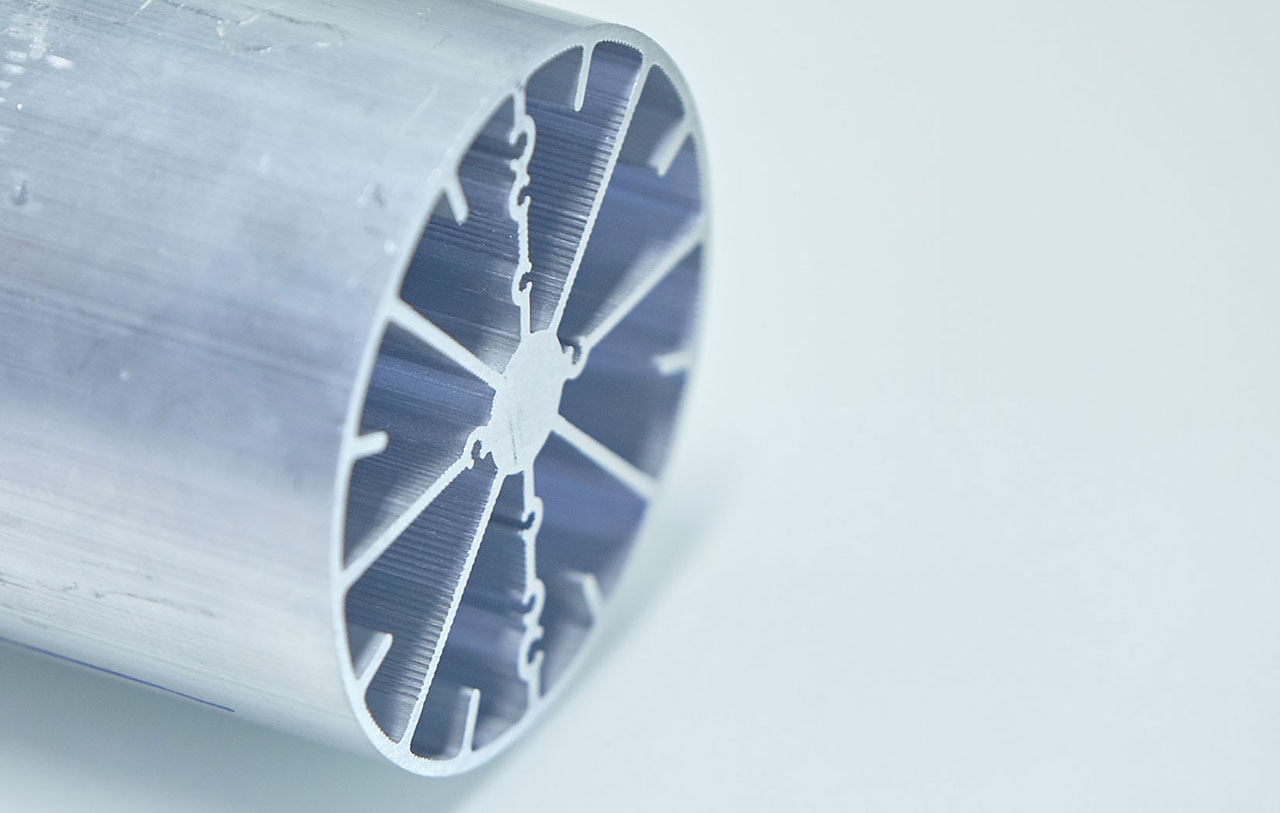

You need Perfect Profiles

The design of a perfect profile starts from the idea of creating it by analysing every detail, thanks to everyone’s collaboration for a common goal: perfection.

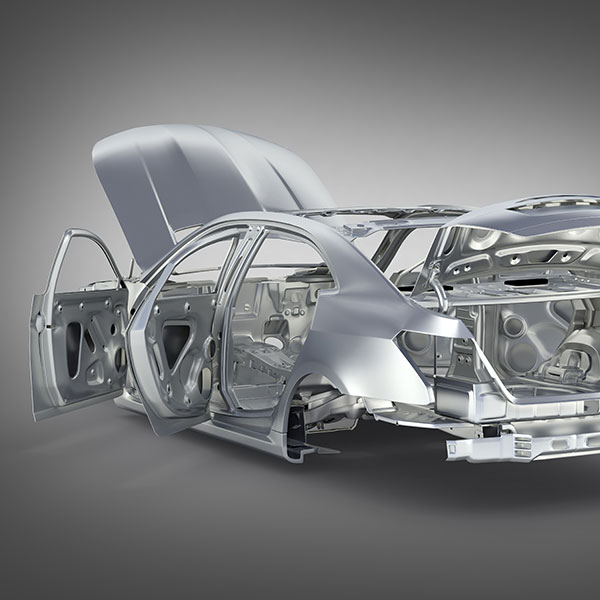

We Know what You Need

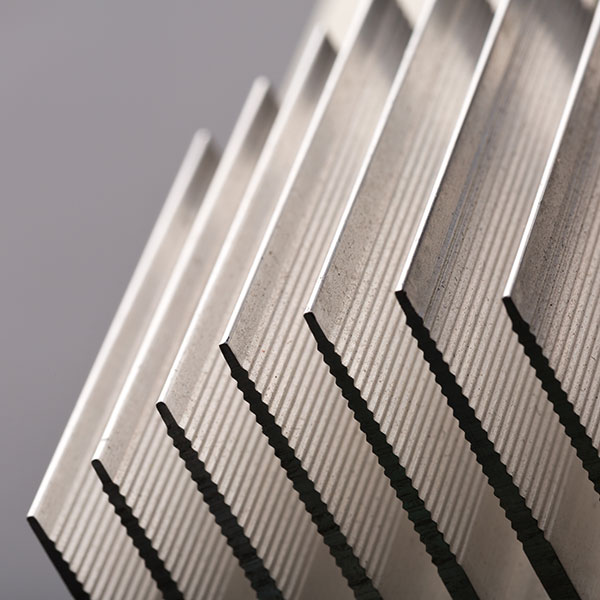

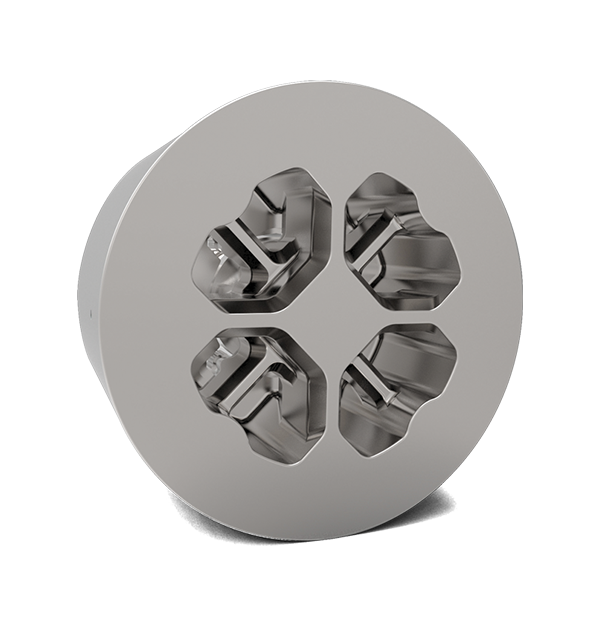

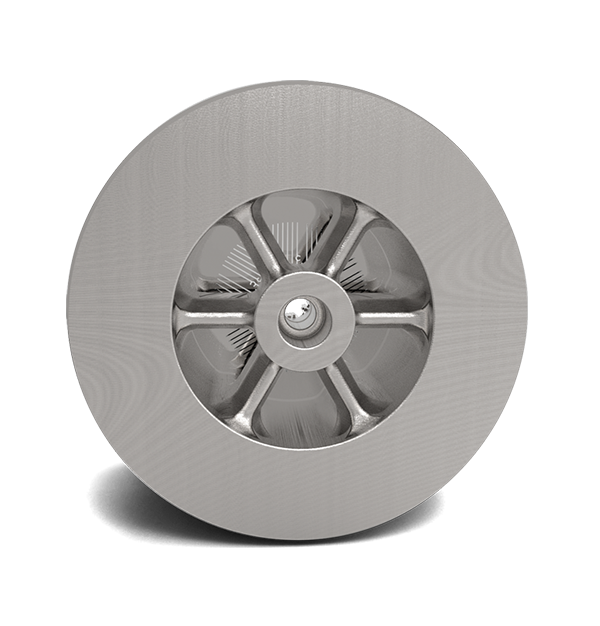

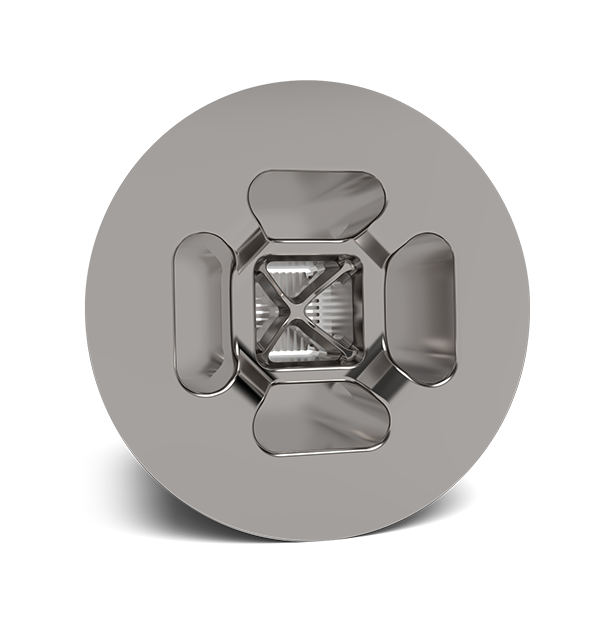

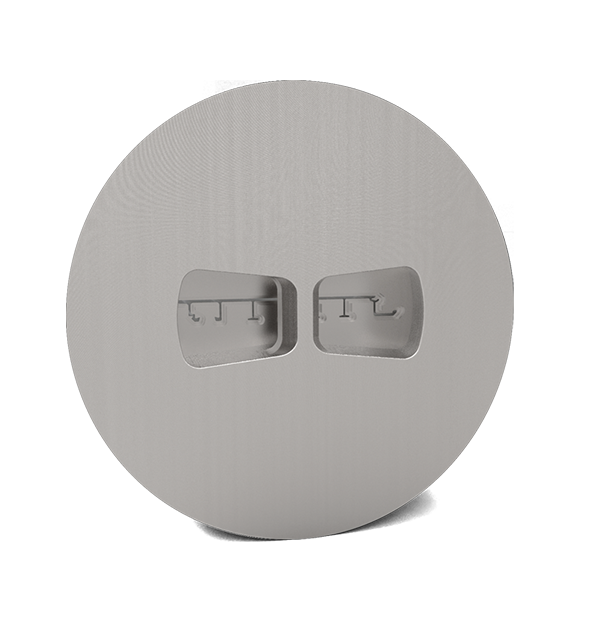

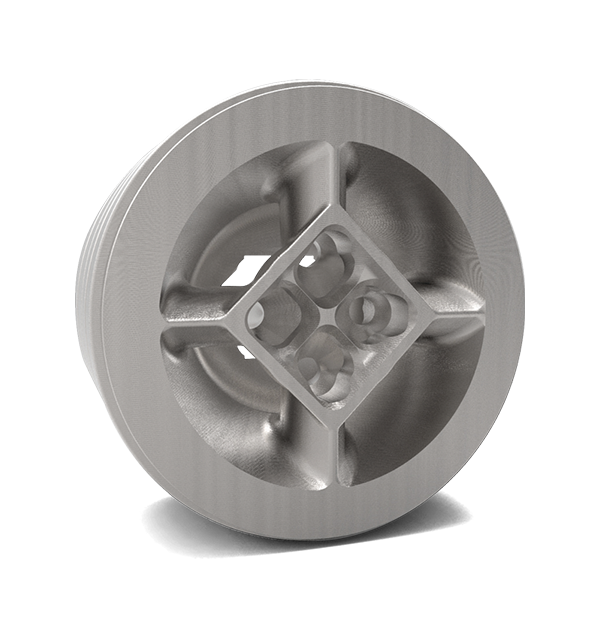

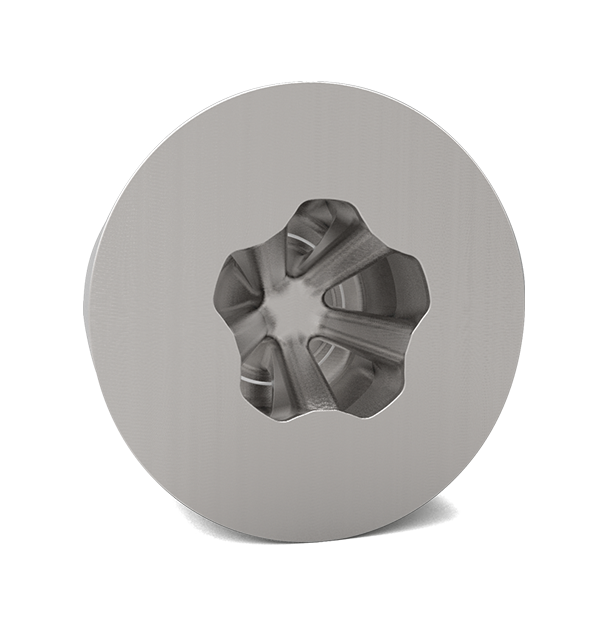

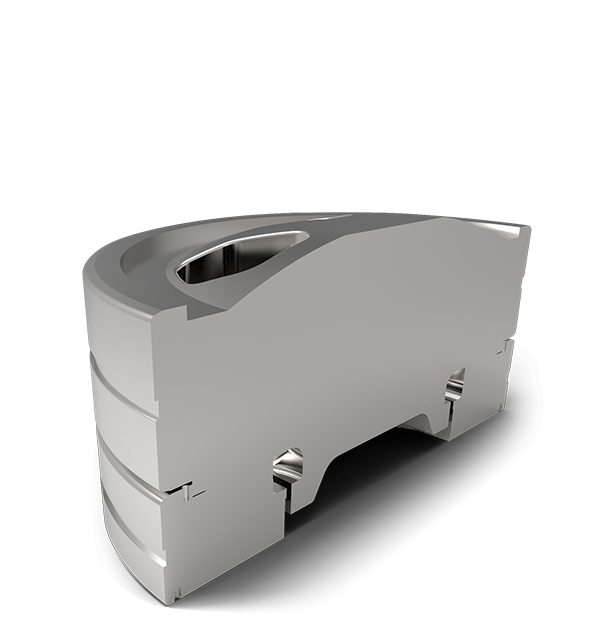

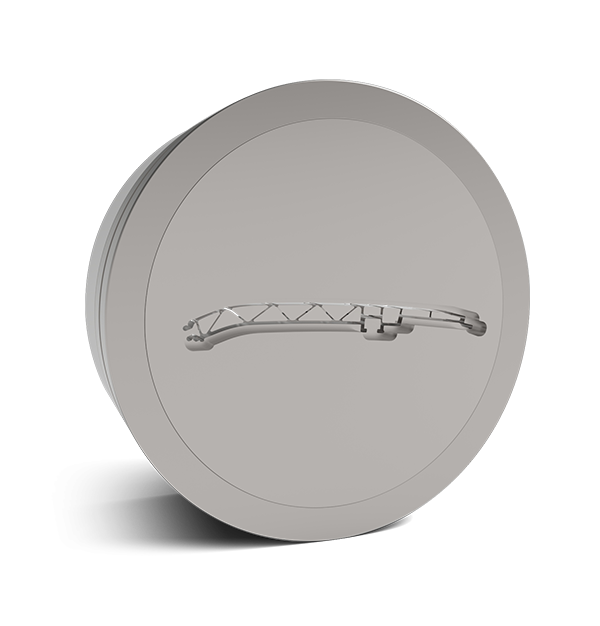

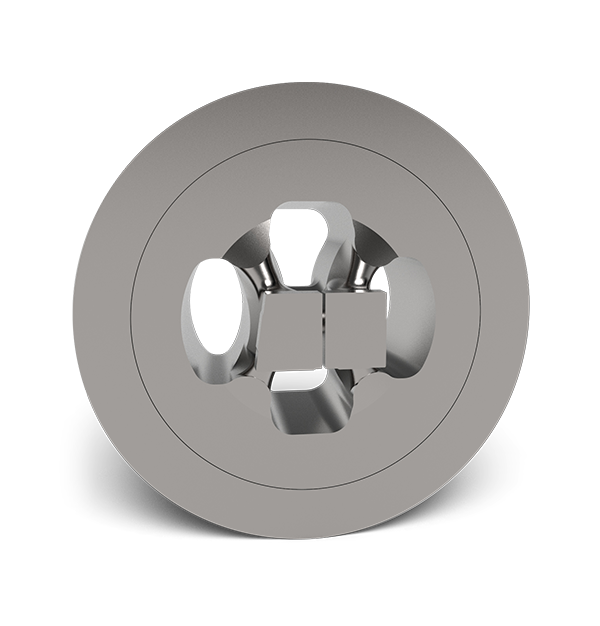

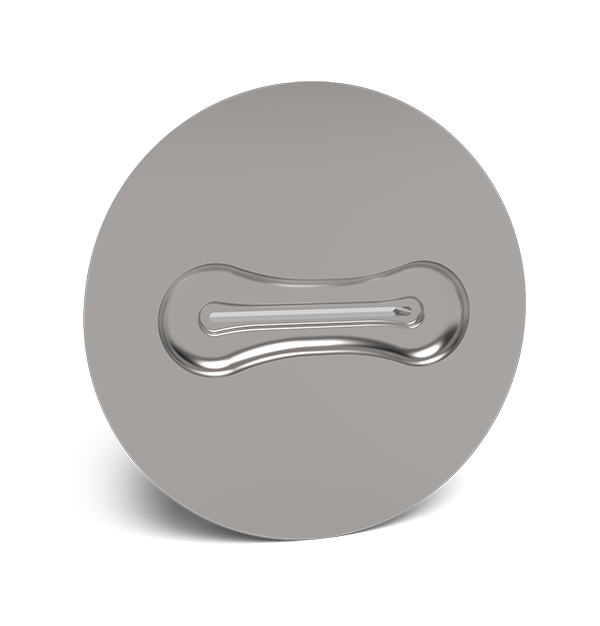

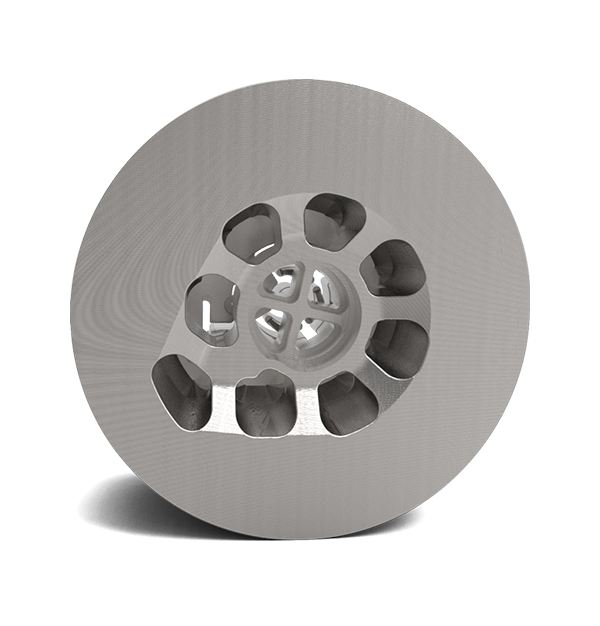

Some of the Alumat dies and their Peculiarities

We Can Do It

Here’s how

with Research & Development

We are constantly evolving to propose new solutions and we study new approaches to the problems faced daily by the profile extruders.

with Quality

We do things right. Everything! Because Quality is an essential element.

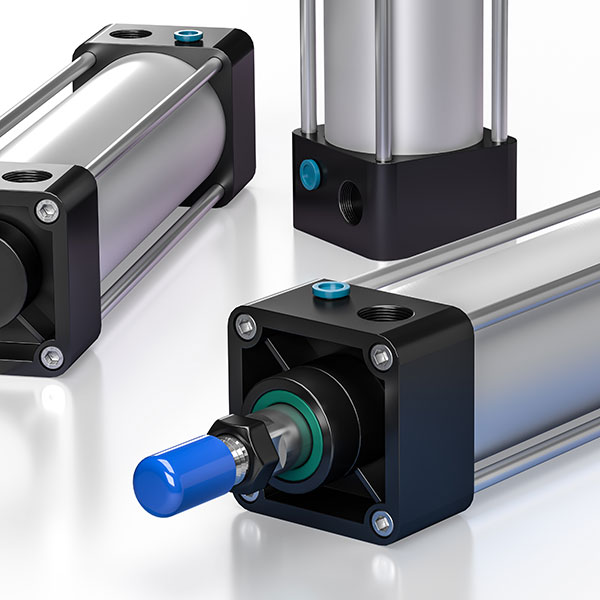

with Technology

We are equipped with what you need and the expertise to make the best use of the available technology. And this goes beyond the “machines”.

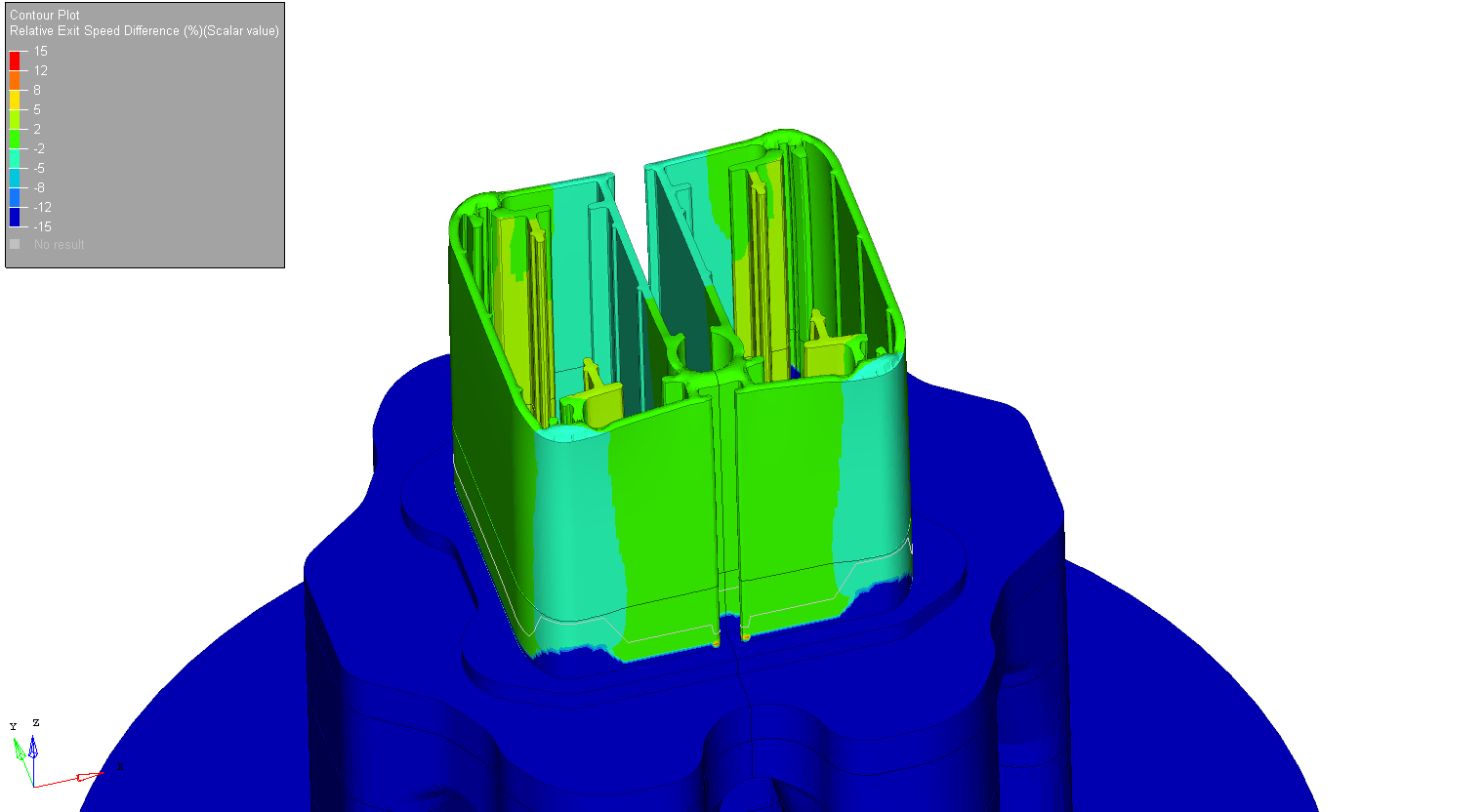

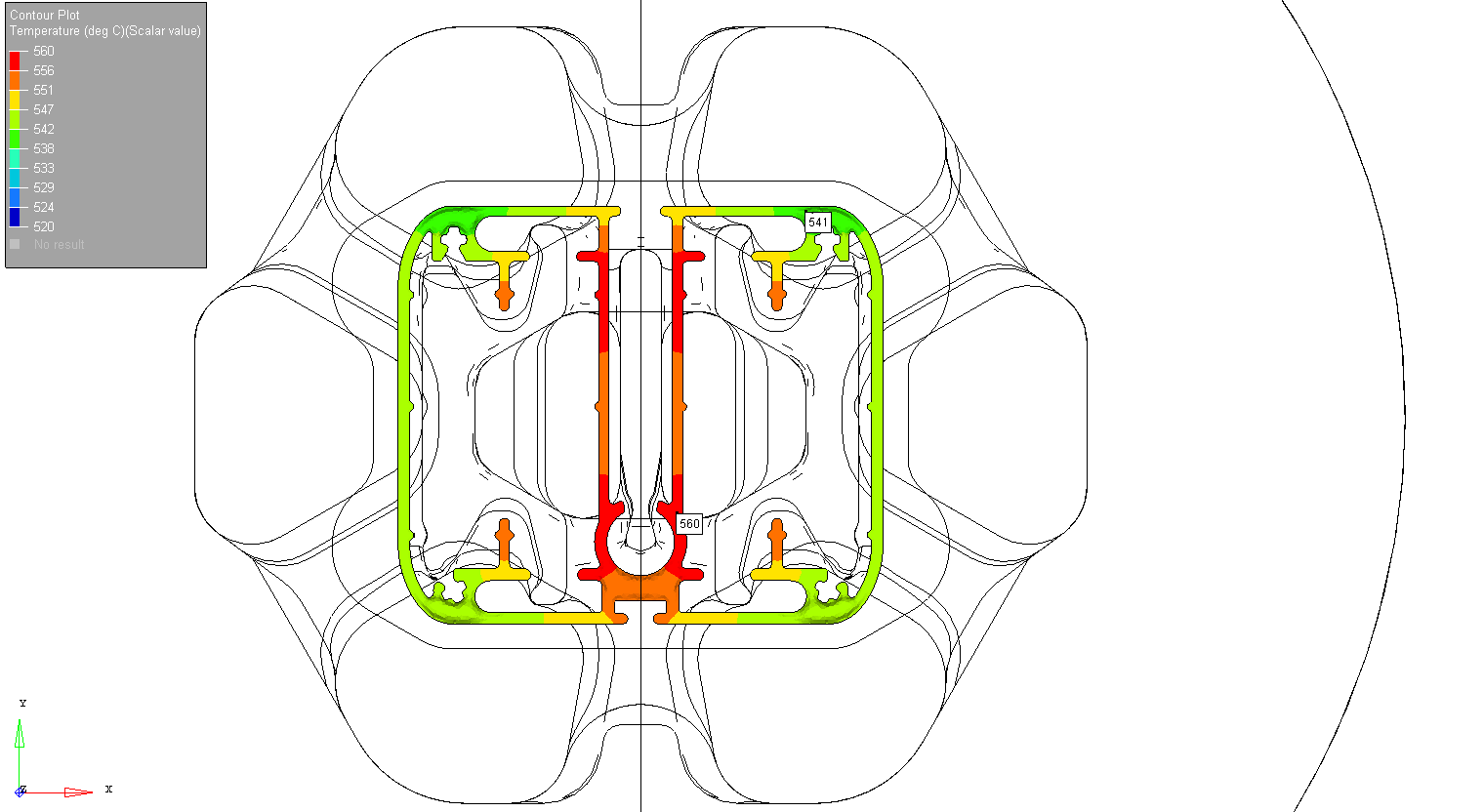

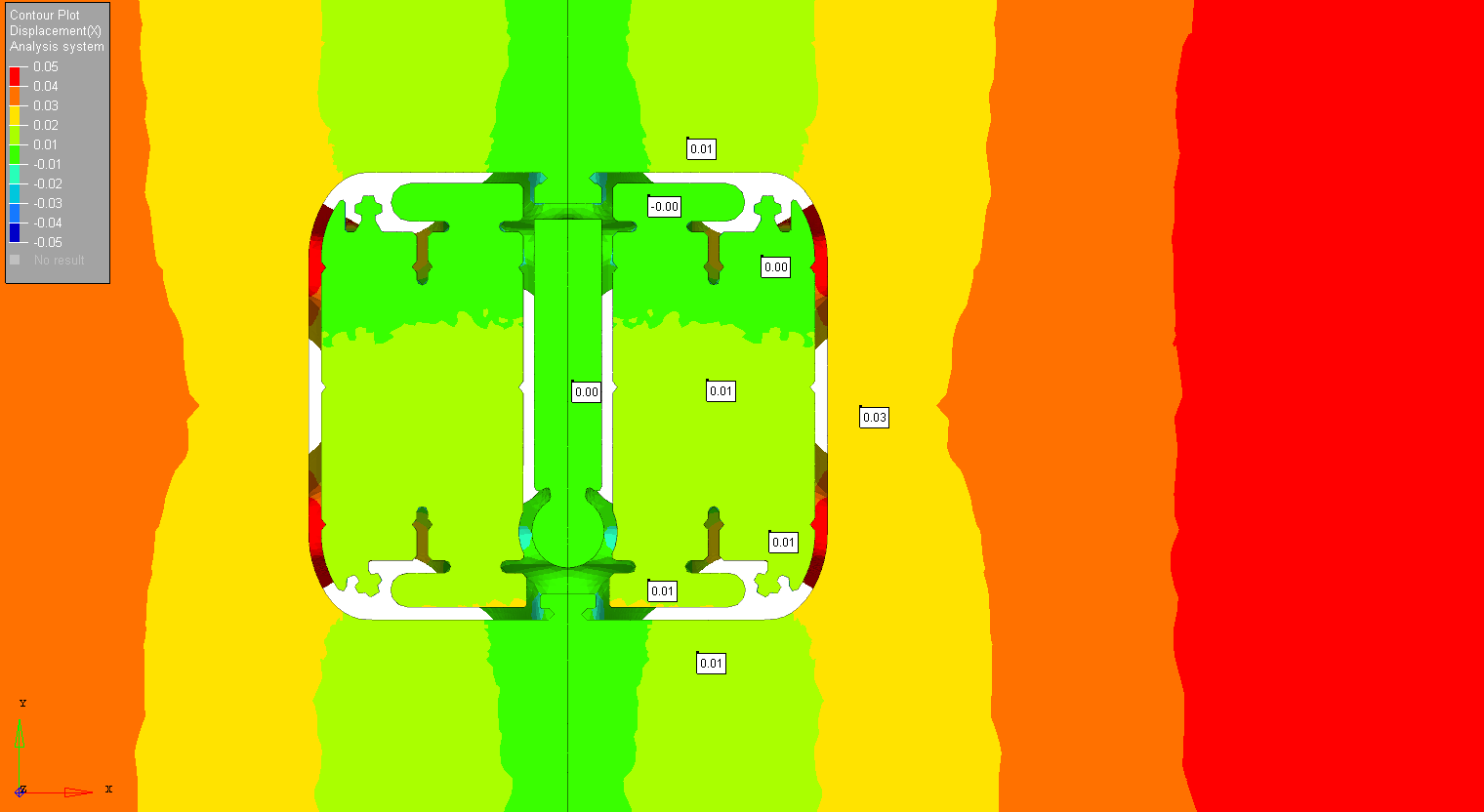

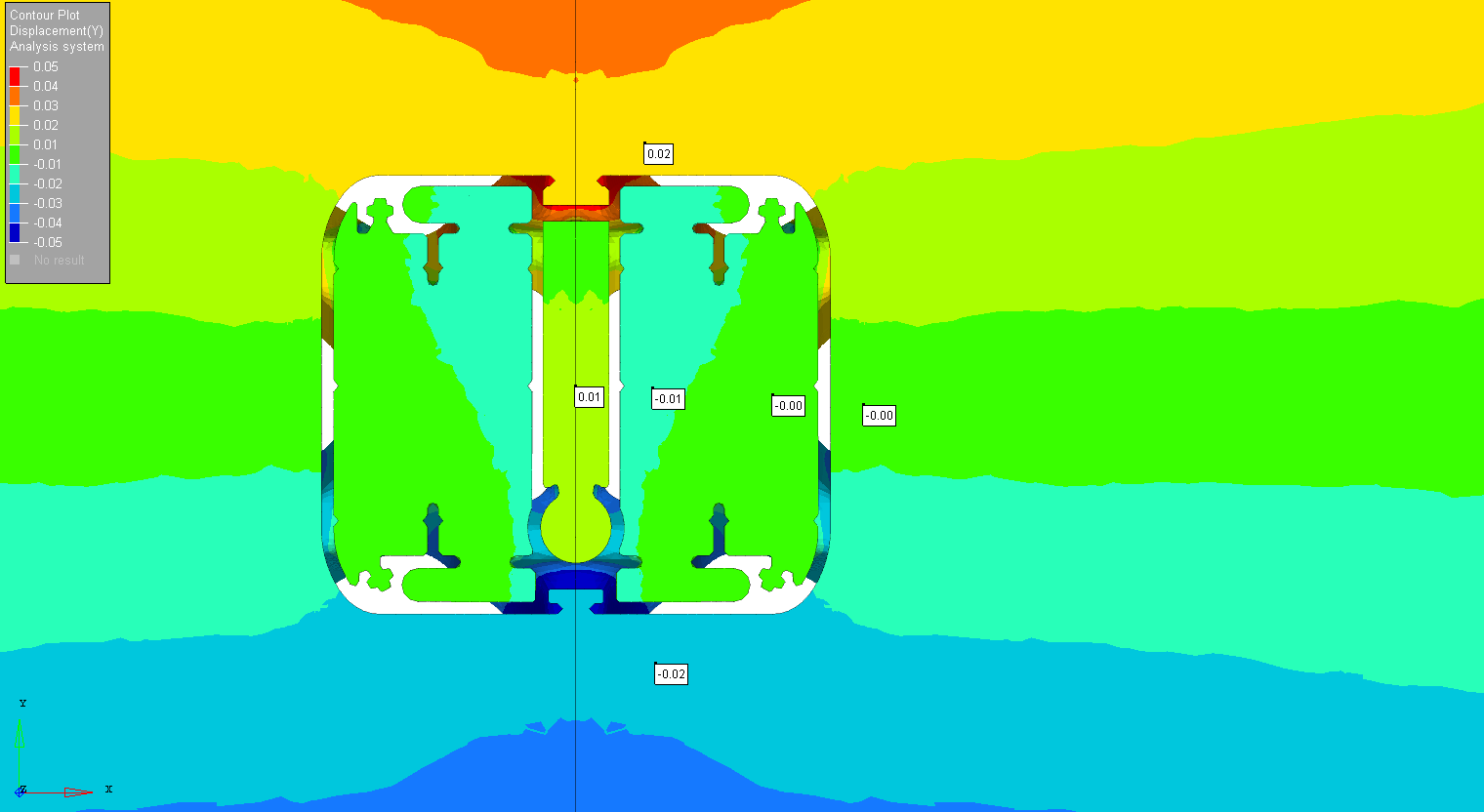

with the Simulation:

the main tool of our Quality and Precision

Alumat has been developing the simulation system for 12 years, in collaboration with the Alma Mater Studiorum of Bologna, Athesina Studiorum of Trento universities and the Altair software. Our group was the first to develop and use this tool, which allows us to foresee the aluminium pressure, the movements of the madrels, the aluminium speed and so on...

Moreover, we take part in a benchmark every 4 years, to always be updated about the improvements of the “standard” simulation and its results that are released by the new versions.